The benchmark in sophisticated measurement technology

Give your quality assurance the touch of perfection

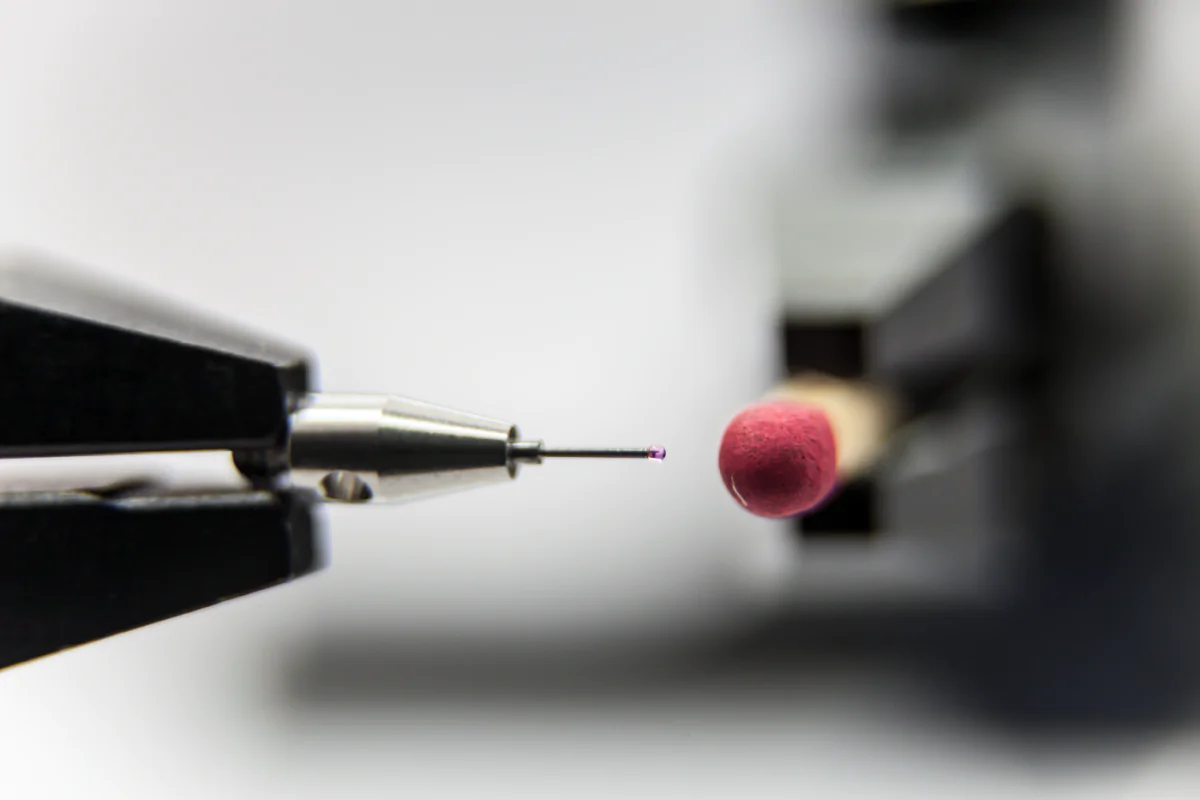

KOMEG manufactures the complete Mitutoyo stylus program. Customers worldwide rely on our experience from five decades of pioneering stylus and material development.

Industrial quality assurance requires more and more universality, flexibility and the ideal shape for absolute precision.

This is where our styli show exactly what they can do: maximum precision, groundbreaking innovation and convincing cost-effectiveness.

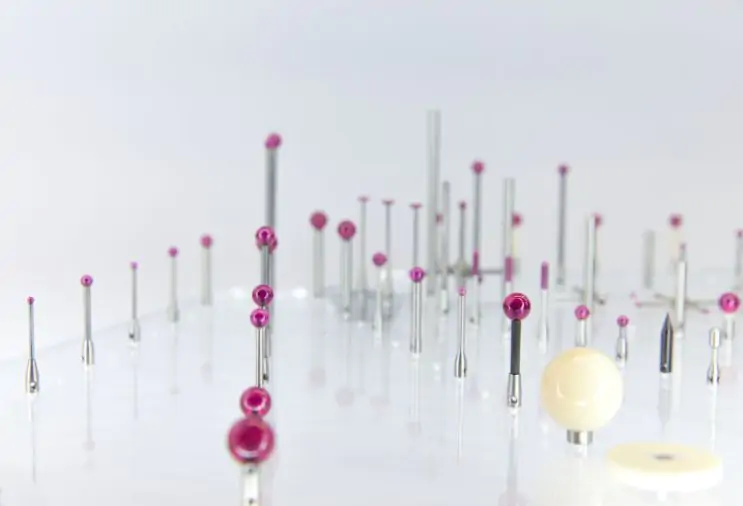

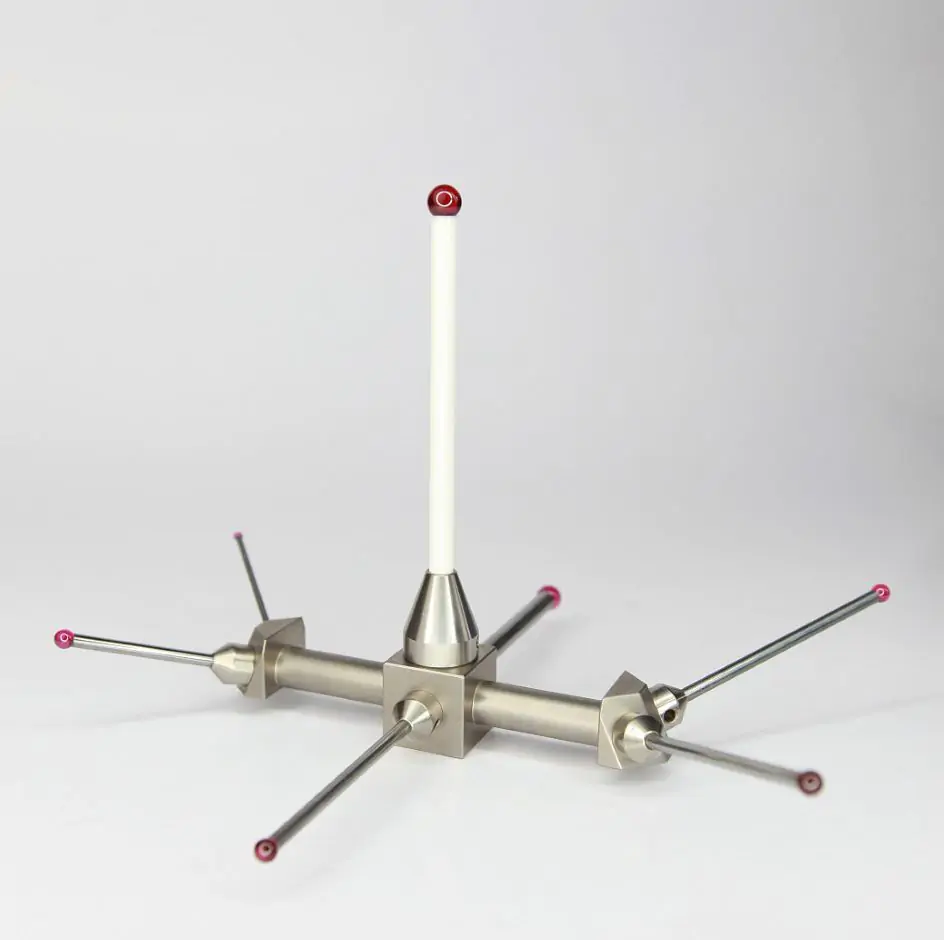

Standard styli

Steel, aluminum or ceramic? Ruby, zirconium oxide or silicon nitride?

The Mitutoyo product range includes more than 600 probe components as well as highly specialized devices that offer the best possible solution for your specific measuring tasks with a great deal of sensitivity.

The flexible overall concept is constantly being further developed to meet user requirements.

Our service includes

- advice on the choice of suitable stylus combinations

- repair of high quality probes

- replacement of defective stylus tips, holders and shafts with quality guarantee

Ball materials

RUBY

As the second hardest of all stylus materials, ruby is the perfect all-rounder when it comes to producing spherical contact points that need to be highly wear-resistant. Probe balls made of ruby have been tried and tested for decades for most standard applications.

The low specific density of ruby compared to other stylus ball materials makes it possible to minimise the mass of the stylus tip as low as possible.

SILICONNITRID

Silicon nitride is extremely hard, extremely wear-resistant and has the lowest surface roughness of all ball materials.

Special advantage: Aluminium is not attracted to silicon nitride, so that the aluminium particles do not

aluminium particles are not deposited on the silicon nitride surface.

However, scanning steel materials with silicon nitride ball styli is not recommended, as the abrasion significantly changes the spherical shape.

ZIRCONIUM OXID

Due to the specific surface properties of contact points made of zirconium oxide - a ceramic compound - they are the best choice for aggressive scanning of abrasive surfaces, such as cast iron workpieces.

The composite structure of zirconium oxide ensures the right wear resistance for the task at hand.

Shaft materials

STAINLESS STEEL

Non-magnetic stainless steel components are used in stylus production for both shafts and bases. Styli with a length of less than 30 mm are often manufactured with one-piece base bodies in order to offer the best ratio between bending stiffness and weight.

TITANIUM

Titanium has a relatively low density, good bending stiffness and thermal stability. Titanium is the material of choice for bases, end pieces and extensions when low weight and good rigidity are required.

ALUMINIUM

Aluminium is a lightweight material and is used for stylus extensions and other large-format components.

Due to the considerable thermal expansion at higher ambient temperatures, stylus components made of aluminium are best used in thermally stable and air-conditioned environments.

CARBON FIBRE COMPOSITE MATERIAL

The high-quality composite material with a coefficient of thermal expansion of almost zero is also very light and extremely rigid. CFRP can be used as a solid material and as a tube and is particularly suitable for the manufacture of long styli.

TUNGSTEN CARBIDE

Due to their high bending stiffness, tungsten carbide shafts are used for styli with balls smaller than 1 mm and a length of up to 50 mm. The higher density of tungsten carbide often restricts a longer stylus length due to the specifications.

CERAMIC

Ceramic offers a low ratio of thermal expansion and density ratio, while it has a slightly higher bending stiffness than steel and is therefore an ideal material for stylus shafts when steel is too heavy. It is available from a diameter of 2 mm and is therefore used for stylus spheres from 2.5 mm.

Special styli - custom configuration

Individual design and precision manufacturing of styli are part of our special solutions. According to customer specifications, we undertake individual production in special shapes and deviating material combinations.

One option is the modification of Mitutoyo standard probes of all common formats, e.g. we shorten or extend probe tips of standard probes for roughness and form.

For non-standard measuring tasks, we develop and manufacture device- and task-specific probe configurations.

They enable optimal measurement

- of the surface condition in small bores or deep grooves

- difficult-to-access radii and steeply angled surfaces

- when using rigid touch probes, such as the SP80

- When scanning workpieces made of aluminum or superhard materials

Our website is currently still under construction. More information and more detailed content will be added in the near future. Thank you for your understanding- visit us again soon for the latest updates. If you have any questions about our products and services, please contact us using the contact details provided.