Our Process

We follow a detailed process to find the customised solution that best suits your specific needs.

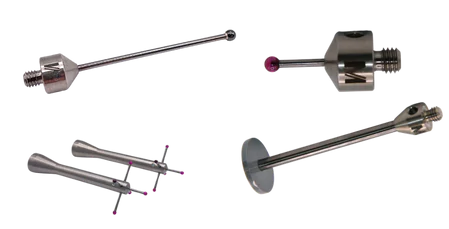

SPECIAL MEASUREMENT TECHNOLOGY

Precision and efficiency in quality assurance

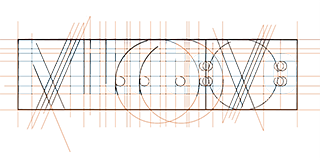

Special measurement technology enables companies to perform more precise and efficient measurements and thus ensure the quality of their products. This involves the development of special measuring methods and equipment tailored to the individual requirements and needs of a company.

High-precision measuring devices and customized measuring methods are used that can detect deviations in the micrometer range. In addition, measurements can be carried out faster and more efficiently, which leads to an increase in productivity.

One-stop solutions for measurably better results

KOMEG special measuring equipment uses five decades of innovative development experience to offer customized solutions for the design of measuring stations. From workpiece feeding to post-control of production machines, we implement individually developed special solutions. Our customer-focused full-service engineering optimizes costs and simplifies after-sales support. Our solutions are tailored to the specific test parts, test sequences and process environment of a wide range of industries and offer high operational reliability and availability. Our equipment is easy to operate and can be easily used by workers, even in complex processes.

Special Measurement Technology Products

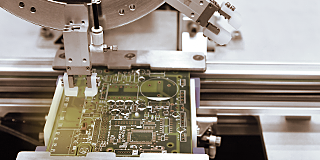

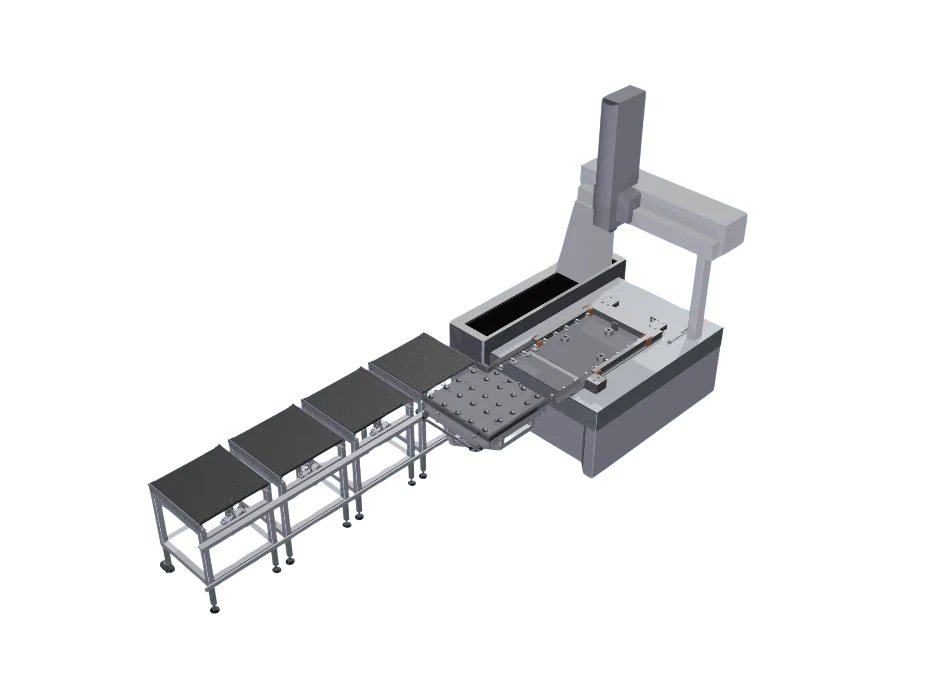

LOADING SYSTEMS

Economic operation of coordinate measuring machines

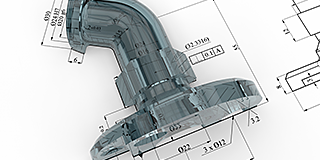

Loading systems play a crucial role in automating and increasing the efficiency of measuring processes. They enable measuring equipment to be loaded and unloaded quickly and precisely, resulting in improved productivity and accuracy.

KOMEG's modular loading technology shifts the setup processes in front of the measuring device, thus minimizing test times due to the fast part change.

The position-defined, reproducible positioning of the workpieces provides reliable measurement data - even for optical test methods and micro parts.

A wide variety of system variants are possible - from manual to automated setup and measurement operation without operator intervention.

The interlinking of measuring device with active fixtures and automatic feeding system enables serial testing and 100% random sampling.

If required, the feeding solutions are supplemented with adapted protective enclosures and thermal/climate cabins, thus ensuring defined temperature and room conditions.

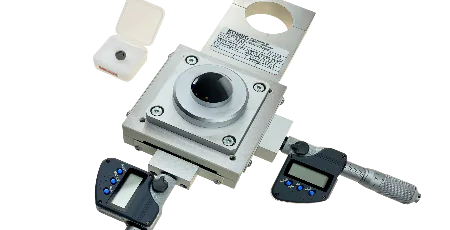

For serial measurements with improved efficiency and the handling of heavy workpieces

our Manual Pallet loading System, MPS is the serious option.

The stations are available as a standard solution for different Mitutoyo frame sizes

for the MiStar, CRYSTA-Apex V and STRATO-Apex models:

On request, the MPS can be customized for other brands.

The systems consist of MPS Manual Pallet Station base, Lowering Monitor System LM for feedback to the software

that the pallet is in measuring position and several optional pallet handling steps.

AUTOMATION

Testing in time with production

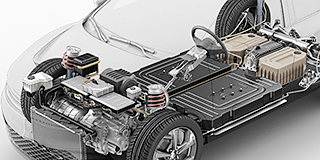

Automation in metrology plays an important role in improving the efficiency, accuracy and reliability of measurement processes. It enables measurements to be taken automatically, and data to be acquired and analyzed without the need for human intervention.

We concentrate our special solutions expertise in automated measuring systems with different levels of integration. In inline or post-process controls, they optimize test cycles and manufacturing processes.

We develop customer-specific SPC measuring systems - right up to automatic testing machines that perform series tests in real time at the pace of production.

We have extensive experience in the direct connection to machines with correction value transfer to the machine control.

As a complete package, we implement automated workpiece feeding and automatic sorting functions.

We develop parallel measuring stations and networked multi-station systems for high test part volumes and extensive series testing programs.

Smart Factroy Cell - How to organise your production intelligently

You want to know more about our individual special solutions?

Contact us and we will be happy to help you!